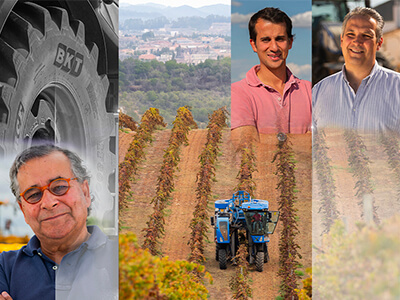

We also have one more guest today: Bruno Santos. Bruno is a BKT Field Engineer for OTR, with responsibility for South-West Europe.

His extensive knowledge in tire industry products and services, their applicability and market needs, allowed him to take part of multidisciplinary teams who outlined a vision and consequent strategy to create value for the organization.

Bruno, come and join us! Bruno, warm welcome to the show.

Thank you.

Gentlemen, welcome back. So, I assume you’ve been listening to my interviews with Thomas and Alexander, Bruno and I bet you have found them just as interesting as I did.

So, what do you think, in general, about what they had to say? How can companies embrace this move towards net zero?

It’s a good question! There are initiatives both on the OEM side and from users, but it’s those on the OEM side that – from our perspective as a tire manufacturer – have more impact.

But let’s look at the general picture. Rather than attempting to find ways of electrifying the really big dump trucks, they’re instead downsizing dump trucks. It’s been described as moving from elephants to ants. In this way, battery weight and capacity are less of an issue. Plus, you get a larger fleet, which collectively means less downtime and more productivity – which is what all the mining companies want. It’s a game-changer for us – smaller machines mean smaller tires, different technologies.

Or you can go for electric drive – still using a diesel engine, but rather than direct drive to the wheels, you use it to turns an alternator that powers electric wheel motors. That reduces fuel use, reduces carbon footprint, and with fewer overall mechanical components, you’ve got another low maintenance machine that improves truck availability. Add in a trolley assist system – where the electric power is supplied by overhead lines, just like a train or a tram – and you get the best of both worlds.

Bruno, you mentioned the end-user initiatives too.

Yes, there’s a really good example – I know this one because we’ve got BKT tires in some of their plants! It’s a joint initiative between EQIOM, one of France’s biggest building material suppliers, and Air Liquid – they’ve built the first carbon-neutral cement plant in Europe. It captures, then liquifies, the CO2 produced, before pumping it into empty oil wells in the North Sea. They expect to capture around 8 million tons of CO2 during the first ten years of operation.

OK, that’s interesting – it’s good to see those initiatives at the processing stage too, not just in the extraction phase.